Rubber Tracks for Compact Track Loaders & Mini Excavators

Compact Track Loader Rubber Tracks

TNT rubber tracks are manufactured from only the finest materials specifically designed to provide excellent performance under a wide range of working conditions. Tough rubber compounds help provide wear and tear resistance and a long service life. Continuous steel cables and specially designed compounds are engineered to provide high strength and excellent resistance to normal undercarriage wear and damage. Precision forged and heat treated steel link assemblies laminated with multiple stranded, high tensile strength steel cords are treated to provide one of the most durable tracks in the industry.

Dare to Compare:

Standard Aftermarket vs TNT

TNT supplies only the best products to our customers. Every rubber track we make has been subject to our rigorous quality check and meets or exceeds our customer?s expectations.

This is a comparative cross section sample of a TNT rubber track and a standard aftermarket track:

- Reinforced Roller Path for longer life

- Endless Heavy-Duty Steel Cables for thick, uniform cords which provide added strength and longer life

- Natural Rubber Compounds meaning less filler and better durability

Compact Track Loader Track Patterns

MULTI-BAR

- Great traction and flotation

- Smoother ride, less vibration

- Less intrusive footprint when traveling across turf

- Made with premium engineered rubber compounds

- Perfect for paved surfaces and great for snow removal

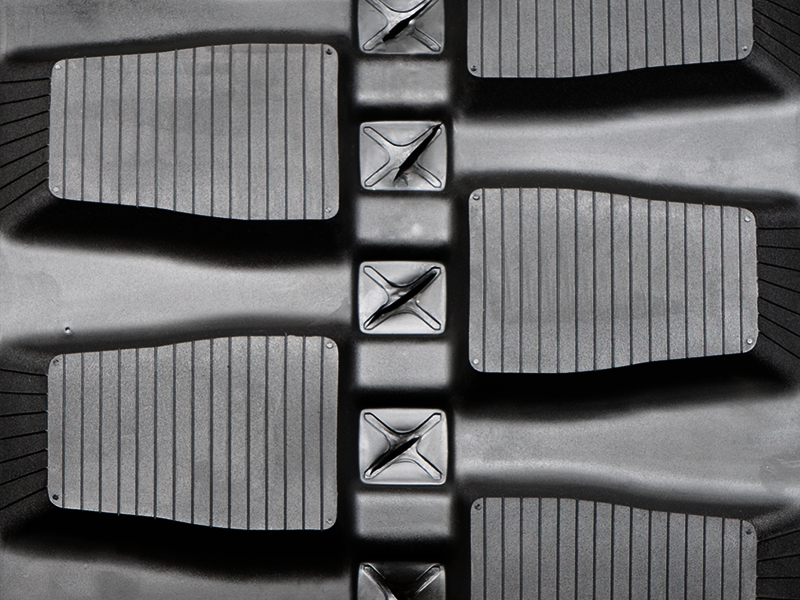

BLOCK

- Most common OEM tread design

- Versatile multi-purpose track

- Large lug for great traction

- Made with premium engineered rubber compounds

- Built to handle any job while providing good traction

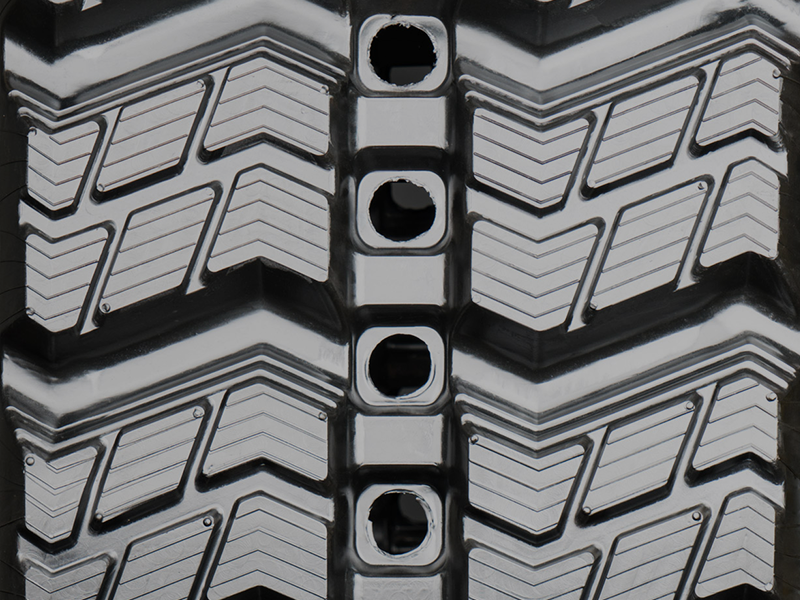

C-PATTERN

- Common OEM tread design

- Multiple biting edges offer excellent traction

- Perfect for muddy conditions and soft dirt

- Made with premium engineered rubber compounds

- Optimal service life in demanding environments

XT-Pattern

- Bar pattern with extra biting edges

- Grips better than OE track patterns

- Perfect for applications needing extra traction

- Made with premium engineered rubber compounds

- Optimal service life in demanding environments

BD-Pattern

- Less soil and turf disturbance

- Low vibration, improved ride quality

- Cut resistant rubber compounds

- Bi-directional tread pattern increases traction

- Reduced ground marking and increased flotation

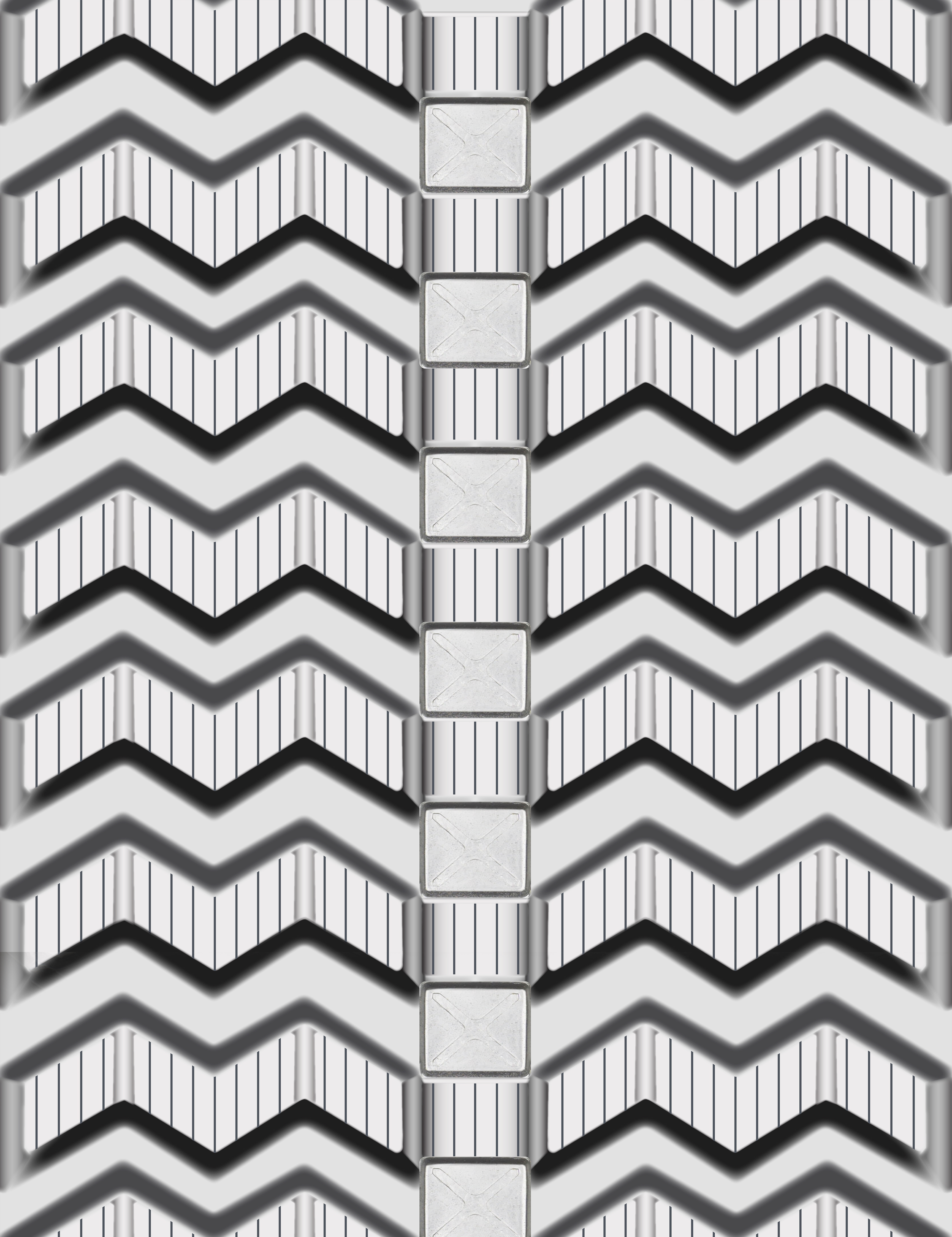

Z-Pattern

- Bar pattern with extra biting edges

- Grips better than OE track patterns

- Works well in ice and snow

- Made with premium engineered rubber compounts

- Perfect for applications needing extra traction

ZB-Pattern

- Sawtooth bar tread provides excellent traction in mud and snow

- Excellent general-purpose track that offers superior all season performance

- Great flotation for minimal ground disturbance

- Continuous steel cables for increased durability

Mini-Excavator Rubber Tracks

TNT mini excavator rubber tracks are typically modeled after OEM tread designs and guide systems. With a multitude of undercarriage guide systems available on the large range of these machines we pride ourselves on providing the best fitment available for your specific model.

TNT strives to provide its customers with the right tracks that are designed specifically for the undercarriage system to provide a smoother, quieter, longer wearing track.

Key Advantages:

- Improved roller path

- Heavy-duty steel lugs

- Thick steel cables go through three step coating process to ensure bonding to the rubber

- Steel cables are machine wound and tensioned for even placement in the tracks

- Smoother ride that creates less vibration which results in reduced operator fatigue and machine wear