Steel Tracks, Hybrid Tracks & Track Pads for Mini Excavators

EXCAVATOR STEEL

TRACKS & PADS

Our steel chain links, made from a high-precision forging process, are heat treated to ensure durable core tenacity and hardness in the areas exposed to extreme wear. The heat-treatment reduces the chipping caused by violent knocks or strikes. All steel chain parts are high-precision machined. Additional hardness through heat treating is done on all critical wear areas.

- Track Assembly: Complete track groups are built with top quality precision parts. All parts are hardened and tempered to prevent cracking under extreme conditions to keep your machine operational.

- Track Chains: All of our track links are forged from top quality 35Cr and 40Cr carbon chromium steel. The track link body is manufactured to a hardness of HRC33~37 and the top surface of the track links are manufactured with an induction heating process to a hardness of HRC52~56.

- Track Shoes: All of our track shoes are milled into a long profile from top quality manganese boron steel billet (23MnB). The profiles are then precision cut to the required length and both bolt-holes and mud-holes are punched out to accommodate for the required sizes.

HYBRID

TRACKS & PADS

TNT?s hybrid tracks provide you with the strength of steel tracks and the flexibility of rubber. Hybrid track systems deliver excellent traction for any demanding environment. Compared to traditional rubber tracks, hybrid tracks are the most durable, cost effective alternative.

Each rubber pad is molded to the grouser for a quick and easy change with only a single piece and four (4) bolts. Hybrid tracks are the perfect track system to reduce downtime, eliminate the cost of replacement rubber tracks and perform at a higher level than any conventional rubber tracks available. Our chains will provide you with many years of service without the fear of snapping cords or costly downtime.

Each hybrid track width is optimized to enhance your machines performance. Each pad comes with all the hardware needed including nuts and bolts.

- Grouser: Made from high strength steel. The grouser is heat treated and forged for maximum durability and strength.

- Rubber Compound: The rubber is bonded to the grouser utilizing the latest industrial bonding methods. The rubber is manufactured to be long-lasting and durable.

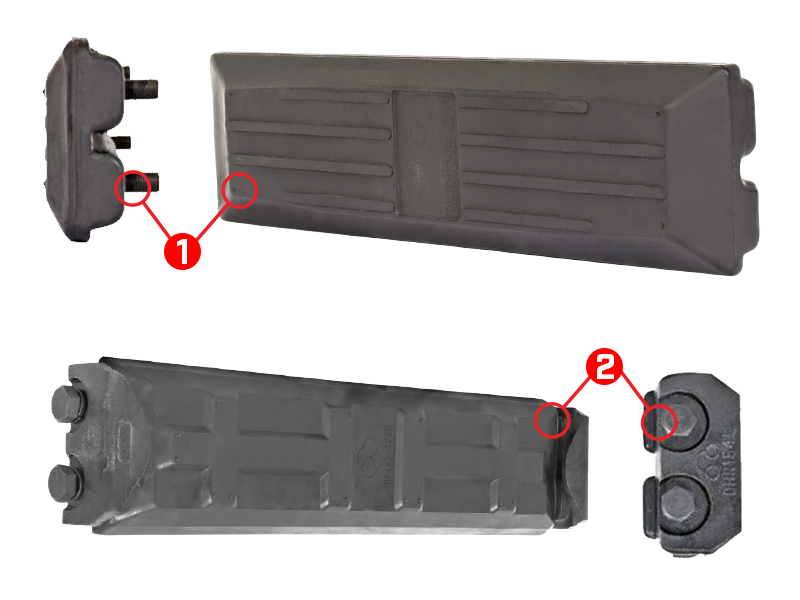

BOLT-ON AND

CLIP-ON PADS

- Bolt-On Rubber Track Pads: The rubber TNT bolt-on track pad is easily attached to the steel grouser shoe by having threaded studs located at the back of the rubber pad, bolted through predrilled holes in the grouser shoe. Most machines already have these holes predrilled by the manufacturer, or the holes may always be drilled into the shoes for later use.

- Clip-On Rubber Track Pads: TNT clip-on rubber track pads attach quickly to the steel grouser shoe. Our track pad attaches directly to the steel shoe with a bolt-on bracket at each end. This permits you to easily access the bolt and nut to either add, replace, or remove the rubber track pad. These pads work with most machines with little or no modifications.